Wireless Foot Pedal

The new wireless foot pedal solution from Lazer Safe is a modular technology that enables press brake manufacturers to easily integrate SIL 3 wireless functionality.

Overview

The wireless foot pedal solution is available as an option for press brake manufacturers using the PCSS-A1 or PCSS-A2 platform and makes it easy to incorporate wireless functionality into your machines by integrating the wireless module into your existing foot pedal or designing a new pedal from the ground up. The wireless system uses a safe, dual-channel SIL 3 communications method with two-way communication between the press brake and the foot pedal while also providing dynamic range and position monitoring through the use of ultrasonic sensors.

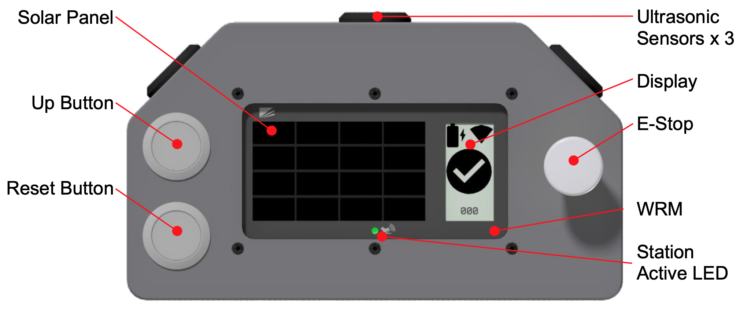

*Image shown as an example of an OEM foot pedal layout.

Key features

The wireless foot pedal system uses a dual-channel SIL 3 communication method with two-way communications between the press brake and the foot pedal. The wireless technology has been developed by Lazer Safe and CE Certified by TUV Austria.

An array of ultrasonic sensors installed in the foot pedal and on the press brake are used to triangulate the position of the foot pedal. The operating range and distance are configurable and automatically monitored.

The system is extremely energy efficient due to the design of the dual-channel wireless transmission system, low power e-paper display, low power illuminated emergency stop button and indoor solar charging cell.

Traditional wireless systems generally need to be recharged daily. The low power technology developed by Lazer Safe is unique in that the foot pedal can operate for up to one month before the battery requires a plug-in recharge.

The supplied lithium ion battery holds enough charge for up to one month of usage before it needs to be plugged in to recharge. There is a connection on the remote module to allow for USB charging of the battery without having to remove it from the foot pedal station. The machine operator can simply connect the foot pedal to any USB charger.

The integrated solar charging cell provides continuous charge using ambient light to extend the life of the battery until a plug-in recharge is required. Depending on the ambient lighting conditions, the solar cell can extend battery life by up to 20%.

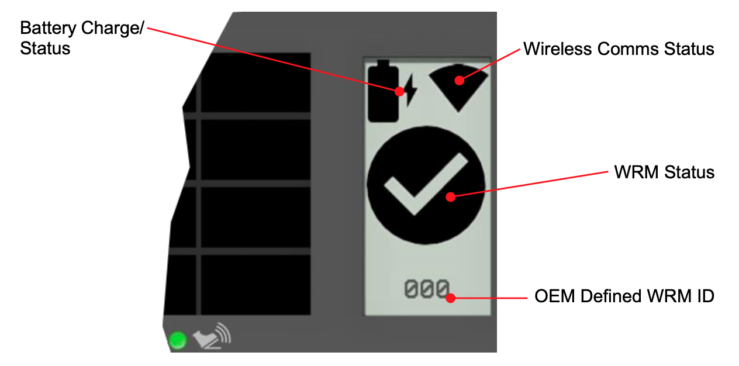

A low-power E-paper display is incorporated into the foot pedal and shows critical user information such the current battery status, wireless connection status, active/sleep mode plus more.

Hardware

The wireless pedal system comprises three main hardware components;

- Wireless Remote Module (WRM); installed inside the foot pedal together with a set of three ultrasonic sensors.

- Machine Module (MM); fitted to the press brake and provides the wireless link between the WRM and PCSS-A.

- Ultrasonic Module (UM); fitted to the press brake and together with ultrasonic sensors in the MM, monitors the position of the foot pedal.

Wireless Remote Module (WRM)

The wireless remote module is a self-contained unit that includes;

- 12 pulsed safety inputs (6 dedicated and 6 spare).

- Dual integrated antennas

- E-paper display

- Indoor solar charging cell

- Rechargeable lithium ion battery

- Connections for external USB charging port and wireless pairing button

- Pedal active status LED

Also supplied and connected to the WRM are;

- An illuminated (red LED) emergency stop button

- A set of three ultrasonic sensors

Of the 12 inputs on the WRM, 6 inputs are preconfigured for the following functions;

- Down pedal x2 (NO and NC contacts)

- Emergency stop button x2 (NC contacts)

- Reset button x2 (NO and NC contacts)

Of the remaining 6 spare inputs, these can be custom configured for any auxiliary button functions such as the up pedal, upper and lower tool clamping, etc.

E-paper display

The low-power display shows information to the machine operator such as battery level, wireless signal strength and in-range status. The foot pedal identification number can be defined by the press brake manufacturer and also displayed on the CNC to show the operator which foot pedal is paired with the machine.

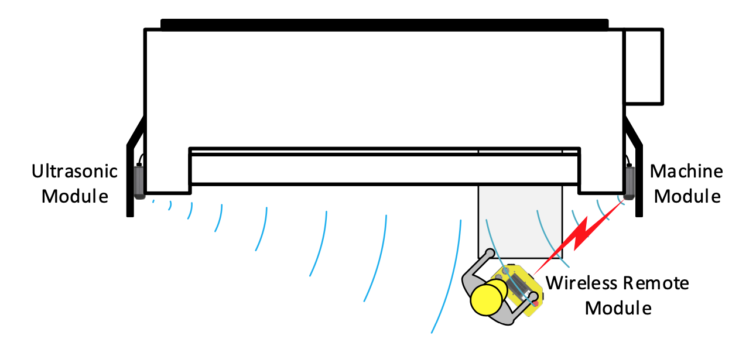

Machine Module (MM) and Ultrasonic Module (UM)

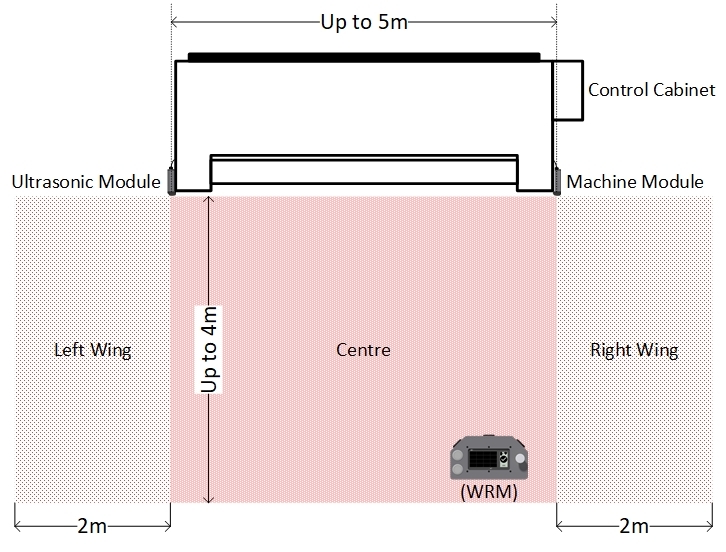

The Machine Module (MM) and Ultrasonic Module (UM) are fitted to the lower front left and right ends of the press brake. The MM is mounted on the press brake and interfaces between the PCSS-A and the Wireless Remote Module (WRM). The MM communicates wirelessly with the WRM, and also contains a set of two ultrasonic sensors. The UM contains an additional two ultrasonic sensors.

The total combination of seven ultrasonic sensors located in the WRM, MM and UM are used to triangulate the position of the foot pedal in relation to the front of the press brake.

Ultrasonic sensors

The active operating area is divided into three regions in front of the press brake; the centre, and the left/right wings. The ultrasonic sensors in the MM and UM track the location of the Wireless Foot Pedal and ensure that the operator can only operate the press brake when within the defined safe operating area and within clear line-of-sight of the machine.

This prevents the machine from being operated if the foot pedal is outside the defined active area or hidden behind a screen or wall.

Application Example

This video shows how the Italian press brake manufacturer Vimercati has incorporated the wireless module into the design of the foot pedal. The light-weight design improves ergonomics and usability.

Key benefits

Benefits for the press brake manufacturer

- By far, the simplest, fastest and most cost effective way to incorporate wireless technology and integrates via the existing PCSS-A platform.

- The only complete wireless safety solution with TUV CE Certified hardware and software.

- Design flexibility - incorporate into the existing foot pedal design, or design a new pedal from the ground up.

- Flexibility to incorporate additional wireless controls and functions.

- Flexibility to tailor wireless functionality and customise the user interface in the CNC via SmartLink.

Benefits for the machine operator

- Improved ergonomics. The operator has more freedom to move and position the foot pedal.

- Simple and intuitive operation.

- Reduced operator fatigue.

- Eliminate trip hazards.

- Eliminate potential for cable damage.

- Clear floor space makes it easier to move trolleys and carts around the front of the press brake.

- Long battery life means operators can focus on bending parts without having to worry about frequent recharging. The foot pedal can be easily recharged by connecting to any USB charger or a USB port on a PC or the CNC.

Contact Us

If you are a press brake manufacturer, contact us to find our more about our wireless technology and OEM solutions.